Harness the Power of Process Analysis for Growth and Efficiency

Business Process Management

OUT-OF-THE-BOX TOOLKITS FOR PROCESS TEAMS

Streamline and optimize your business processes with powerful modelling and analysis capabilities. Gain valuable insights, identify bottlenecks, and drive efficiency to achieve your business goals faster and smarter.

| COMMON CHALLENGES WITH BPA | OUTCOMES WITH THE BPA SOLUTION |

|---|---|

Inconsistent and duplicated view of current business processes | Standardized mapping of the current process landscape |

Process modeling activity siloed from business stakeholders | Process teams co-creating processes with business owners; |

Wastage and bottlenecks across the process landscape | Improved operational efficiencies and productivity |

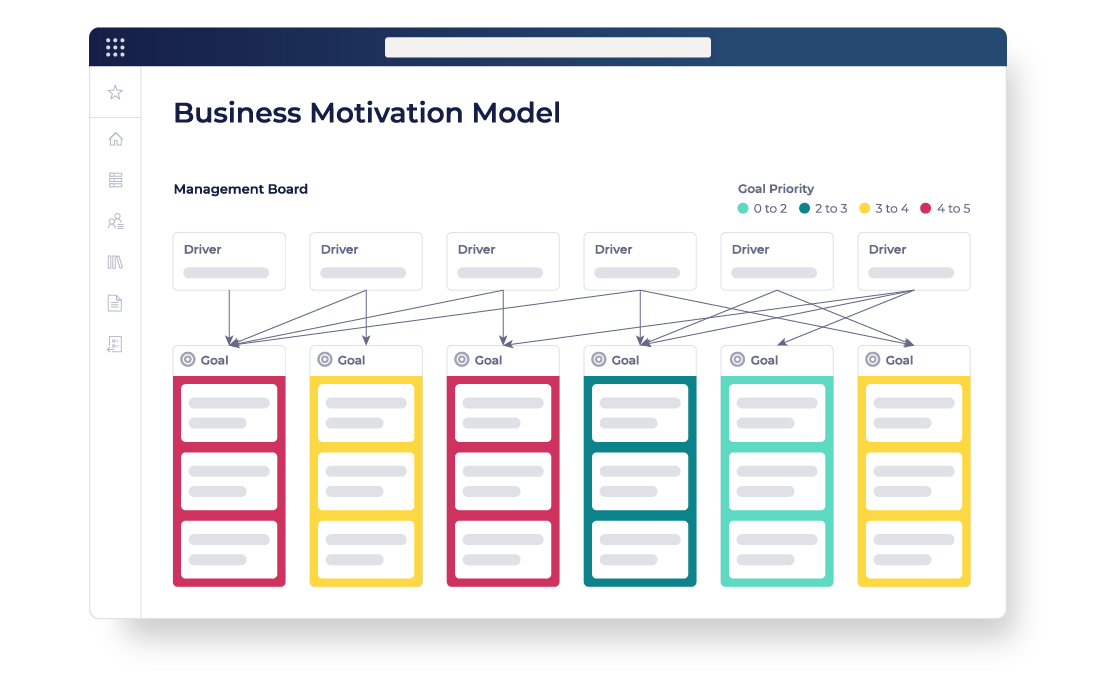

Processes disconnected from strategic direction | Business processes aligned with business strategy and goals |

Blurred view of customer touchpoints and experiences | Enhanced consumer satisfaction with optimized customer journeys |

BUSINESS-CENTRIC processes

Maximise business value with powerful process analysis tools

Streamline your operations

Identify bottlenecks, eliminate waste, and optimize workflows for enhanced productivity.

- Pinpoint inefficiencies and process gaps.

- Automate manual tasks and reduce errors.

- Streamline communication and collaboration.

Enhance customer experience

Delight customers with streamlined processes and personalized interactions

- Identify and eliminate customer pain points

- Optimize customer journeys and touchpoints

- Deliver seamless, personalized experiences

Ensure regulatory compliance

Stay compliant effortlessly by identifying risks, implementing controls and monitoring processes

- Identify compliance gaps and risks

- Automate compliance monitoring and reporting

- Ensure adherence to industry regulations

Improve decision-making

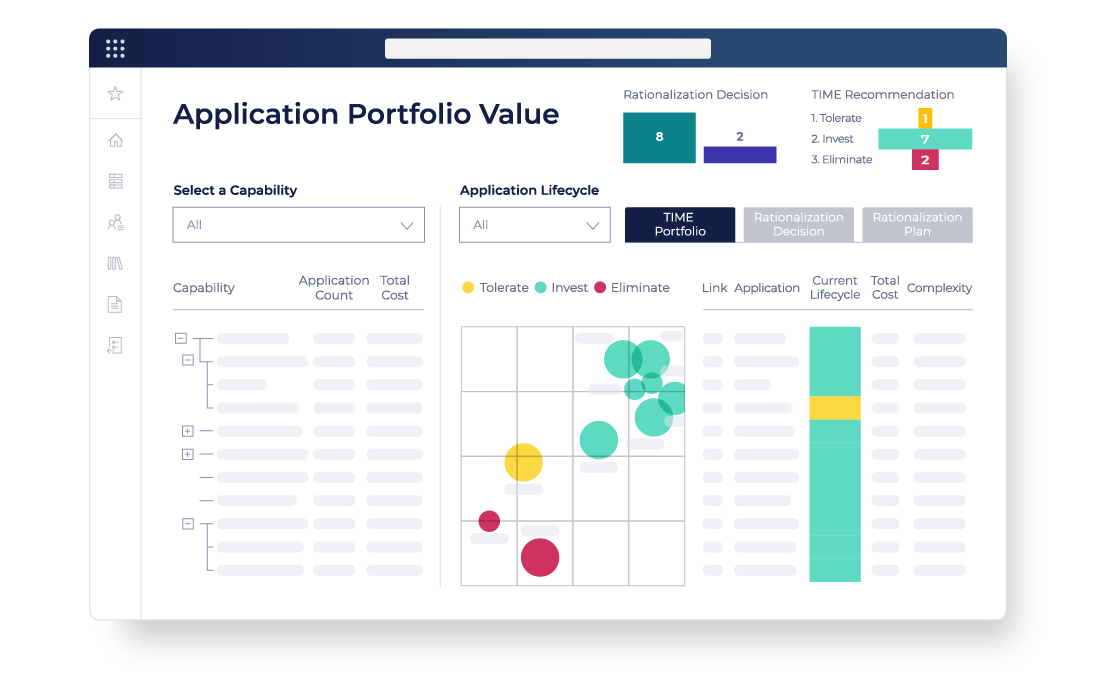

Make informed decisions with actionable insights derived from data-driven process analysis

- Identify trends, patterns, and outliers

- Evaluate performance against KPIs

- Forecast future outcomes and opportunities

2024 Gartner Magic Quadrant Leader for EA Tools

Orbus Software leads in 'Ability to Execute' and 'Completeness of Vision' for the third consecutive year.

8 Steps to Start a High-Impact EA Practice

Discover the key strategies and expert insights from Gartner to establish a high-impact enterprise architecture practice

Business process analysis use cases

Define a common language and framework to document, analyze, and communicate processes across your organization

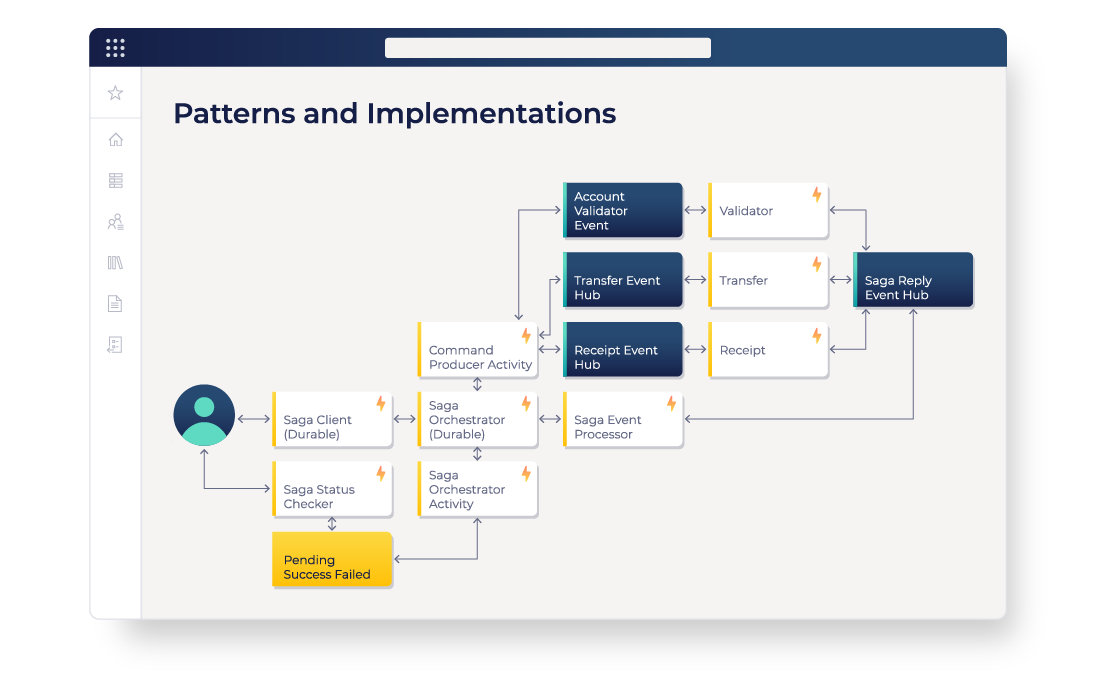

Standardized Process Modeling

- Align to common notation such as BPMN to ensure consistency and interoperability

- Establish best practices for process modeling, including naming conventions, symbols, and modeling rules

- Develop pre-defined templates to facilitate consistent modeling structures and elements across processes

- Share models with process owners and other stakeholders for review, feedback and contribution data

- Implement a governance framework to review and validate process models, ensuring adherence to standards

Business Process Analysis

Systematically examine organizational processes to identify areas for improvement and optimize efficiency, effectiveness, and productivity

- Collect data and performance metrics related to process efficiency, cycle times, and resource utilization

- Identify process bottlenecks, inefficiencies, and areas for improvement.

- Analyze root causes and identify opportunities for streamlining and optimization

Value Stream Modeling

Create visual representations of value streams, identify and eliminate non-value-added activities and streamline processes for maximum efficiency

- Identify value stream boundaries and scope.

- Map the current state of the value stream, capturing process steps, handoffs, and delays.

- Analyze the value stream for waste, bottlenecks, and non-value-added activities.

- Design the future state of the value stream, incorporating lean principles and improvement initiatives.

- Implement the proposed changes, monitor performance, and continuously improve the value stream.

Customer Journey Mapping

Visualize and understand the customer experience, identify pain points, and identify opportunities for engagement and enhancement.

- Identify customer personas and their specific, their motivations and journeys

- Map out the stages and touchpoints of their customer journey.

- Gather data and insights to understand customer behaviors and emotions at each touchpoint.

- Analyze and identify pain points, gaps, and opportunities for improvement.

- Design and implement changes to optimize the customer journey and enhance overall experience.

Kick-start your transofrmation

Related use cases

Business Process Success Story

How Just Group optimized business process management

Just Group uses OrbusInfinity to streamline processes, enhance governance, and centralize compliance, improving risk management and operational efficiency.

business process Resources

Find resources that can help your digital future

Our customers have spoken